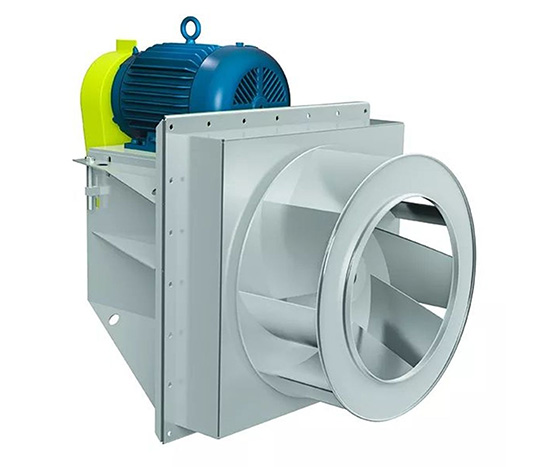

The gas heating indirect gas heating method, it is through the combustion machine in the stainless steel heat energy conversion device combustion, and then through the high temperature induced draft fan and circulation pipe, the hot air transported to the furnace heating, so that the cycle reciprocating heating air, so that the powder curing furnace to achieve the required hot air value. Heat energy converter is made of high temperature resistant stainless steel plate (2 ~ 3mm), the cavity is the introduction of foreign advanced technology, through CAD design, with fast heating, long service life and other advantages. The inner plate of hot blast stove is galvanized steel plate with high temperature resistance and aging resistance. The outer plate is cold rolled steel plate with high quality. The inner and outer wall panels are filled with δ150mm rock wool for insulation. Hot air circulation fan adopts national high quality products, impeller adopts temperature resistant material, with high temperature resistance, low noise, balanced operation and other characteristics. The bearing of fan adopts air-cooled refueling cooling mode to ensure smooth convection circulation of hot air and heat balance in the dry passage. GCF type high temperature fan is used for hot air circulation fan. The powder furnace is continuously adjustable in the range of 180 ~ 220℃, and can adapt to fast shutdown. The time to close the circulating fan is not more than 30 minutes after the burner stops burning. The high efficiency filter system adopts high temperature resistant high efficiency filter, which is installed between the fan suction outlet and the heat exchanger. It adopts "W" movable removable installation mode, with access door left on the side for easy cleaning and installation. The fresh air outlet is located on the inlet side of the box body, and the tuyere is 350×350. It is equipped with high efficiency filter screen and air volume adjustment device. The whole fresh air can be adjusted to ensure the fresh air in the furnace. Advantages Excellent thermal insulation performance. Used for all kinds of workpiece painting, other models can be customized.

The gas heating indirect gas heating method, it is through the combustion machine in the stainless steel heat energy conversion device combustion, and then through the high temperature induced draft fan and circulation pipe, the hot air transported to the furnace heating, so that the cycle reciprocating heating air, so that the powder curing furnace to achieve the required hot air value. Heat energy converter is made of high temperature resistant stainless steel plate (2 ~ 3mm), the cavity is the introduction of foreign advanced technology, through CAD design, with fast heating, long service life and other advantages. The inner plate of hot blast stove is galvanized steel plate with high temperature resistance and aging resistance. The outer plate is cold rolled steel plate with high quality. The inner and outer wall panels are filled with δ150mm rock wool for insulation. Hot air circulation fan adopts national high quality products, impeller adopts temperature resistant material, with high temperature resistance, low noise, balanced operation and other characteristics. The bearing of fan adopts air-cooled refueling cooling mode to ensure smooth convection circulation of hot air and heat balance in the dry passage. GCF type high temperature fan is used for hot air circulation fan. The powder furnace is continuously adjustable in the range of 180 ~ 220℃, and can adapt to fast shutdown. The time to close the circulating fan is not more than 30 minutes after the burner stops burning. The high efficiency filter system adopts high temperature resistant high efficiency filter, which is installed between the fan suction outlet and the heat exchanger. It adopts "W" movable removable installation mode, with access door left on the side for easy cleaning and installation. The fresh air outlet is located on the inlet side of the box body, and the tuyere is 350×350. It is equipped with high efficiency filter screen and air volume adjustment device. The whole fresh air can be adjusted to ensure the fresh air in the furnace. Advantages Excellent thermal insulation performance. Used for all kinds of workpiece painting, other models can be customized.